Pressed parts without cmpromises

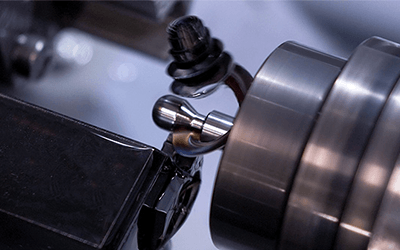

Cold forming

- 2 - 23 mm shaft diameter

- 180 mm length

- Steel, stainless steel, aluminum, titanium etc.

- 2 - 6 multi-stage presses

- Switch from turned to pressed parts

- ISO 14001:2015 / ISO 9001:2015 / IATF 16949:2016

Pressed parts from TIGGES

Never doing anything by chance, defining exact planning processes, providing precise engineering solutions and simulations as well as performing a high-end production with best materials: these are the cornerstones of our activities in the cold forming sector. Trust in us and give us the opportunity to analyze if a switch from your formerly turned to cold formed or combined parts might be possible.

up to 6 stage presses

short throughput times

Process stability

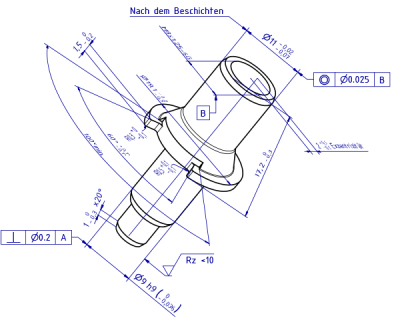

Dimensions and tolerances

The challenge in cold forming is to manufacture the end product directly. This enables us to keep post-processing costs to a minimum and to produce more economically. Our experience since 1925 enables us to manufacture the most complex geometries within narrow tolerance ranges in a process-stable manner.

±0.1mm

Tolerance

180 mm

Length

2 – 23 mm

Diameter

Standard or special material

Materials

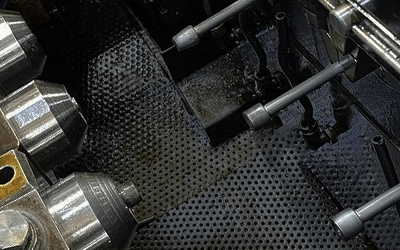

We are processing all materials like steel, stainless steel, aluminium alloys, high-temperature resisting steels, titanium etc. on our efficient and modern machines of up to 6 forming stages. Standard or special materials – we manufacture according to your drawing.

Postprocessing &

Finish

The more complex the component, the more often post-processing steps are necessary. We perform a variety of different finshes.

Heat treatment

Thread rolling

Thread locks

Coatings

CNC-Machining

Grinding

Surface treatment

Markings

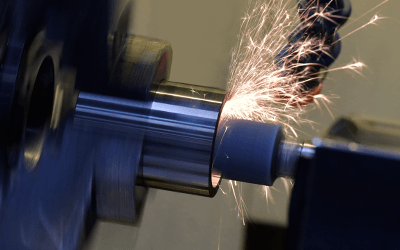

Advantages of cold forming

Cold massive forming is versatile and provides ideal solutions for a wide range of joining requirements.

- Short throughput times

- Low material consumption

- Precise surface structures

- High durability / permanent hardening

- Cost advantages through energy-saving production

- Dimensional accuracy

Quality that connects

Send your drawing

We check your drawing and calculate according to the most cost-efficient manufacturing technology your offer

- non-binding

- flexible production possibilities

- experienced designers

All information transmitted is secure and confidential

Prototypes and small series

As also engineering, tool construction, wire drawing and others are performed in-house, we have the capability and flexibility to produce minimum quantities, like samples and prototypes, with a high profitability.

FAQ's

Cold forming explained

Cold massive forming is versatile and provides ideal solutions for a wide range of joining requirements.

In addition to the high processing speed, we achieve premium quality through dimensional accuracy and high load-bearing capacity. At the same time, we also achieve low material consumption.

The challenge in cold forming is to manufacture the end product directly, without added process steps. This enables us to keep post-processing costs to a minimum and to produce more economically.

The process of cold forming

Cold forming is a high-speed forming process in which hard metals are plastically deformed. The compressive forces that is generated fundamentally changes the material properties, but differs from material to material.

The manufacturing process for the production of connecting elements involves various methods of material processing: Cold forming, thread rolling as well as upsetting and extrusion processes.

As a rule, pressing is conducted in coordinated steps to gradually extract the end product. At TIGGES, this multi-stage pressing is carried out in up to 6 stages.

Applications of cold forming

When we start the production of drawing parts, we ask ourselves which manufacturing process for the desired part is material-friendly and economically efficient.

The strengths of cold forming lies in precise surface structures. It is therefore highly suitable for high-quality installation systems with tight dimensional tolerances. At the same time, this type of production offers cost savings, since comparatively little energy is required with little heat input (due to preheating). Cold formed parts can be produced faster thanks to shorter throughput times. Strength increases with the degree of forming.

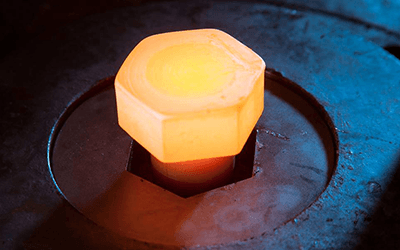

The material also plays a major role. The higher the basic strength of the material, the stronger the forming forces, so that hot forming may be more suitable.

Future of cold forming

The complexity of the machines and systems in which our products are used is constantly on the rise. The components are designed to suit individual applications and spatial conditions.

At the same time, the basic strength and variety of materials are increasing, often reaching the limits of current technologies. Not everyone is able to form copper, for example, because the material is very soft and can therefore only withstand very low loads.

With our machinery, we at TIGGES are already prepared today for the challenges of tomorrow. We rely on our decades of experience in the field of cold forming and know exactly how to implement your project with the utmost intelligence.

Material load for pressed parts

During the forming process, the metal is plastically deformed and then retains its new shape. In order to avoid cracks and defects in the material during the structural change, it is not loaded beyond the material-specific tensile strength. The load limit varies depending on the material.